Home | Testing Services | Technical Information | Consulting | Customer Services | Careers | Contact Us

![]()

►TOYS

►REGULATIONS OF DIFFERENT COUNTRIES

Introduction to EN 71 Part 9 – 11

EN

71-9:2005 + A1:2007 Organic Chemical Compounds –

Requirements

EN

71-10:2005 Organic Chemical Compounds –

Sample Preparation and Extraction

EN 71-11:2005 Organic Chemical Compounds – Method of Analysis

The

Toy(s) Safety Directive states that toys must not present a health hazard by

ingestion, inhalation, skin or mucous membrane contact.

In the

past, the only standard used to assess these risks has been EN71 part 3.

However, Part 3 is limited in that it only considers risks presented by 8 heavy

elements through ingestion.

The EN71

Part 9 – 11 address this limitation by evaluating the risks from certain

organic chemicals through all possible contact routes.

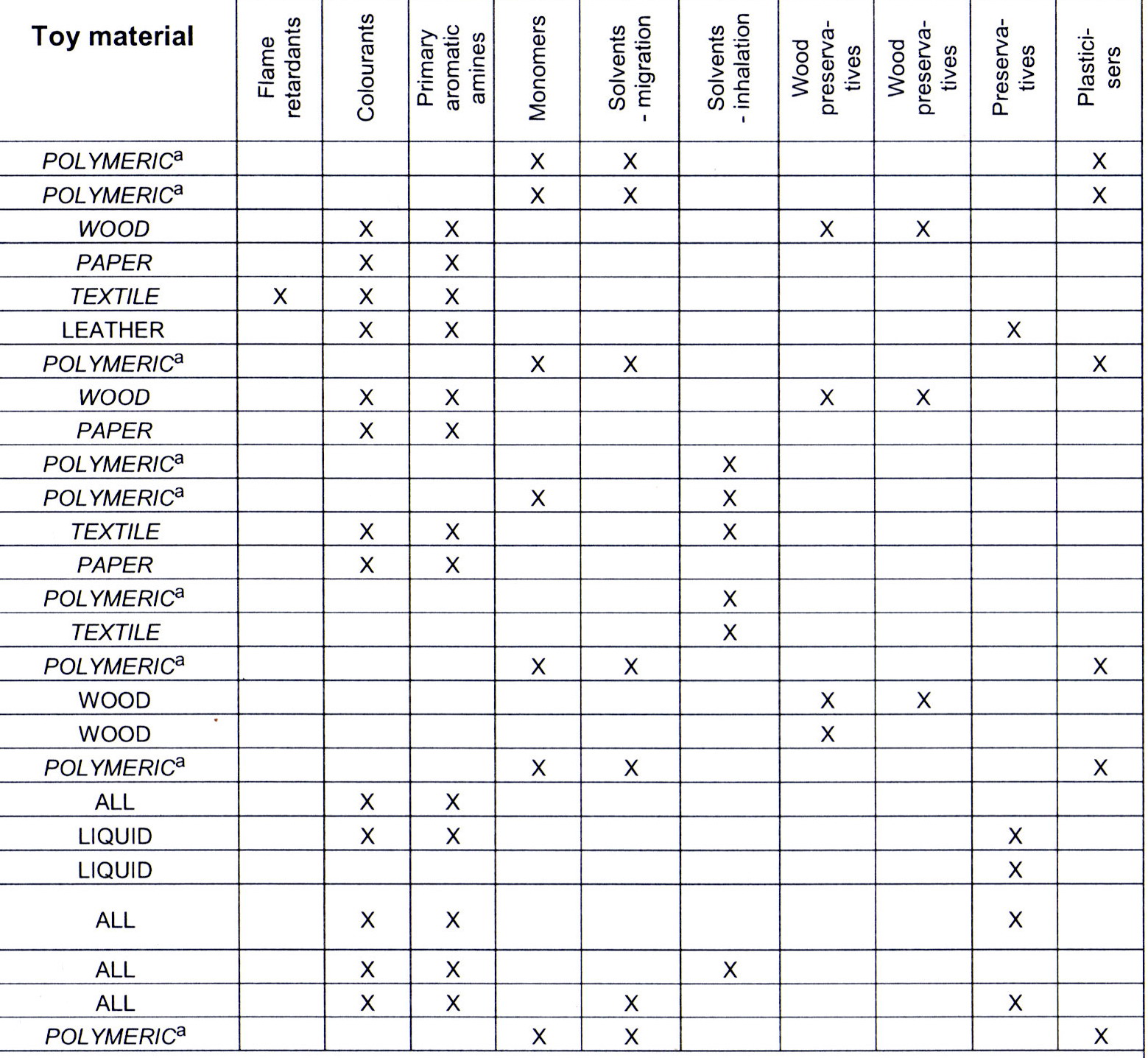

Requirements of EN 71-9:2005 + A1:2007

The following Table summarizes the requirements of EN 71-9:2005 + A1:2007

![]()

Types of toys covered under EN71-9:2005 + A1:2007

(1) Toys intended to be mouthed by children under 3 years of age;

(2) (3) (4) Toys, or their accessible components, with a mass of 150g or less intended to be played with in the

hands by children under 3 years

of age;

(5) (6)

Toys or their accessible components intended for children

under 3 years of age;

(7) (8) (9)

Mouthpiece components of mouth-actuated toys

(10) Inflatable toys with a surface greater than 0.5m2 when fully

inflated;

(11) (12) (13)

Toys worn over the mouth or nose;

(14) (15)

Toys which the child can enter;

(16) Components of graphic instruments sold as toys or used in toys;

(17) Wooden toys (and their accessible components) for indoor use;

(18) Wooden toys (and

their accessible components) for outdoor use;

(19) Toys and components of toys which mimic food;

(20) Solid toy materials intended to leave a trace;

(21) Coloured

accessible liquids in toys;

(22) Non-coloured accessible liquids in toys;

(23) Modelling clay,

play clay and similar, except those chemical toys addressed by

EN71- 5;

(24) Balloon-making compounds;

(25) Imitation tattoos with adhesive;

(26) Imitation jewellery

a = excluding polymeric coatings with a thickness of less than 500 μm

Testing in accordance with EN 71-9:2005

+ A1:2007

Depending

on the types of toys, one or more of the following substance(s) will be

addressed:

Flame

retardants

Colourants

Primary

aromatic amines

Monomers

Solvents-migration

Solvents-inhalation

Wood

preservatives

Preservatives

Plasticisers

Textile

materials

EN

71-9 has requirements controlling the presence of certain colourants; primary

aromatic amines and volatile solvents in textile materials used in particular

types of toys. For toys intended for

children less than 3 years of age containing accessible textile components

there are also requirements for two flame retardants and formaldehyde (see

4.3.1 of EN 71-9).

Fabrics

commonly used by the toy industry include Velboa, Brushed Tricot, Velour and

Microfleece:

Velboa – a soft, medium weight,

short-pile textile with a velvety feel

Brushed Tricot – a polyester (or less

frequently a polyamide) material often used as a lining

Velour – a closely woven, cut-pile

fabric normally of cotton, wool or man-made fibre

Microfleece – a lightweight, double-sided

polyester microfibre.

Chemically

these materials are usually polyester, ‘acrylics’ (polyacrylonitrile), cotton

or polycotton (a blend of cotton and polyester).

Colourants

The 16

colourants controlled by EN 71-9 belong to one of the following classes of

dyestuffs: Disperse dyes, Solvent dyes, Basic dyes and Acid dyes. Apart from the Solvent dyes, they can all be

used to colour textiles. The analytical

method described in EN 71-11 is able to identify and semi-quantify all 16

controlled colourants at the same time using the same analytical

conditions. Therefore, analysis for any

one colourant will also determine the presence of the others. Moreover, with suitable adaptations the

method can be used to identify many other colourants. However, textile materials are not usually

analysed by this rather complicated method unless they have been shown not

to be colourfast when tested by the first-action method elaborated in Annex A

of EN 71-10. This method, adapted from

EN ISO 105-E04, is relatively inexpensive to perform and assesses the

likelihood of colourants being transferred from textiles to the child’s mouth

or skin.

In the

absence of credible evidence that the 16 controlled colourants are not present

or a declaration of colourfastness, textile materials used in toys intended for

children under 3 years of age, and those worn over the mouth or nose, should

initially be tested by the first-action method.

Note that this first-action method cannot on its own be used to show

non-compliance to EN 71-9.

Primary

aromatic amines:

Exactly

the same toys and toy materials that have requirements for colourants also have

a requirement not to contain any of the 9 primary aromatic amines listed in

Table 2C of EN 71-9. These carcinogenic

amines are likely to be associated with certain azo dyestuffs. However, unlike the requirements in the EC

Marketing & Use Directive (2002/61/EC), the standard does not apply to all

textile and leather toys, nor does it require the reductive degradation of any

azo colourants present before analysis for the amines. For textile and leather toy materials the

requirements in the Directive are potentially more onerous but not directly

comparable to the standard – the limits in EN 71-9 are lower than the Directive

but apply only to the free-amine content.

Additionally, EN 71-9 has a requirement for aniline not to be detected

as one of the primary aromatic amines, whereas the Directive currently has no

such requirement. If analysis is being

carried out to check compliance with the Directive, it is extremely easy to

assess compliance with the standard at the same time, and vice versa.

In

exactly the same way that textile materials are not normally analysed for

colourants unless they have first been shown to leach colour when tested for

colourfastness, the same textile materials do not need to be routinely tested

for the presence of primary aromatic amines unless they have already been shown

not to be colourfast. If azo dyes have

not been used, it is unlikely that the textile will contain carcinogenic

primary aromatic amines.

Solvents

(inhalation):

There

are requirements for textiles used in toys that children can enter (e.g. tents)

and for those that are worn over the nose and mouth (e.g. masks) not to release

certain volatile solvents above amounts set for individual substances. Trichloroethylene (which is used to degrease

wool) and nitrobenzene should not be detectable.

The

solvent limits most likely to be exceeded are those for cyclohexanone and

isophorone (3,5,5-trimethyl-2-cyclohexene-1-one). These solvents, which have a strong,

unpleasant odour, are often found present in toys, particularly plastic

inflatable toys, which have a printed surface.

A toy containing a textile material that has a printed plastic coating

may also contain and release these solvents into the atmosphere, especially

when the toy is first taken out of its packaging.

Xylenes

are used as a solvent in the manufacture of polyester fibres and in cotton

finishing. It is possible that traces

may remain in a textile material after manufacture but a toy would be unlikely

to exceed the volatile limit for xylenes unless it contained a large area of

contaminated textile material (e.g. a tent).

Flame-retardants:

EN

71-9 has a requirement that two specific phosphate flame-retardants are not

present in accessible textile materials used in toys intended for children

under 3 years of age. These 2

flame-retardants are more likely to be found in textile materials that are

back-coated with plastics such as PVC than with the textile fabric itself. However, since the analytical method involves

solvent extraction it is likely that a plastic back coating containing these

flame-retardants will cause the textile material to fail the standard. Man-made fibres such as polyester are more

likely to be flame retarded with organic compounds than natural fibres such as

cotton and wool. In the absence of

documentary evidence, toys intended for children under 3 years of age

containing accessible non-woven textiles or textile materials comprising

man-made fibres need to be tested to show compliance. Tri-o-cresyl phosphate, the most toxic

tricresyl phosphate, is far less likely to have been used than

tris(2-chloroethyl) phosphate, but since the analytical method determines each

of these flame retardants there is no extra cost involved in looking for

both. It should be noted that the

analytical method for flame-retardants elaborated in EN 71-11 can also be used

to determine pentabromodiphenyl ether (PBDPE, pentabromodiphenyl oxide) and

octabromodiphenyl ether (OBDPE, octabromodiphenyl oxide) and so can be used to

demonstrate compliance with Directive 2003/11/EC.

Formaldehyde:

Formaldehyde

is most likely to be present in cotton and cotton-containing fabrics such as polycotton

that have been treated to give crease resistance and dimensional

stability. It can also be released from

finishes used on polyester fibres and from binders used in textile printing. Testing to EN ISO 14184-1 is relatively

straightforward: however, it should be noted that the extraction test method is

different from that recommended for child use and care articles in CEN TR

13387:2004.

Plastic

materials

EN

71-9 has requirements controlling the presence of certain monomers, solvents

and plasticisers in polymeric materials used in particular types of toys.

When assessing plastic toy

materials it is important that sufficient information on the chemical

composition is obtained to identify which polymeric

components are present; i.e.

whether the plastic is a copolymer (made from 2 monomers), a terpolymer (made

from 3 monomers) or a blend (alloy) of two or more polymers.

With this knowledge, better

decisions can be taken on the likelihood of one or more monomers or solvents

controlled by EN 71-9 being released and thus needing analysis using EN 71-10

& 11.

Polymeric

materials used by the toy industry include:

Acrylonitrile-butadiene-styrene

terpolymer [ABS]

– a hard plastic that can, inter alia, be alloyed with polycarbonate,

polyurethane and poly(vinyl chloride)

Ethylene-vinyl

acetate copolymer

[EVA] – a flexible (rubbery), transparent plastic made by copolymerising

ethylene with about 6% vinyl acetate.

Polyacrylates [PAc], also known as ‘acrylics’

– a family of polymers which include: poly(acrylic acid), polyacrylamide and

polyacrylonitile. ‘Acrylates’ and

‘Methacrylates’ are thermoplastic resins made from acrylic esters (e.g. ethyl

acrylate) and methacrylic ester (e.g. methyl methacrylate).

Polyamide [PA] – a polymer formed by a

reaction of a diamine and a carboxylic acid, for example, hexamethylene diamine

with adipic acid (Nylon 66), or the polymerisation of ε-caprolactam (Nylon 6).

Polycarbonate [PC] – a hard, clear plastic

made from bisphenol A. It can be alloyed

with many other plastics such as ABS, acrylics and poly(butylene

terephthalate).

Polyethylene [PE] – this translucent plastic

can exist in low density (LDPE), medium density (MDPE) and high density (HDPE)

forms according to its method of manufacture.

It can be copolymerised with vinyl acetate, ethyl acrylate and acrylic

acid.

Poly(ethylene

terephthalate)

[PET] – a polyester made by a condensation reaction between diethyl

terephthalate and ethylene glycol. This

plastic can be blended with polycarbonate.

Poly(methyl

methacrylate)

[PMMA] – a clear, hard, polyacrylate (acrylic polymer) that can be

copolymerised with styrene and alloyed with PVC.

Polyoxymethylene [POM], also known as Acetal

(polyacetal) – a rigid, tough, translucent plastic made by the polymerisation

of formaldehyde.

Polypropylene [PP] – a semi-rigid, translucent

plastic formed by the polymerisation of propylene that can be alloyed (blended)

with poly(vinyl chloride), and plasticized by elastomers such as nitrile

rubbers.

Polystyrene [PS] – available in

general-purpose, expanded and high-impact (HIPS) grades, this plastic can be

alloyed with poly(phenylene ether), also called polyphenylene oxide, and

copolymerised with ‘acrylates’ and ‘methyacrylates’.

Polyurethane [PU] – a thermoset elastomer

that can be blended with ABS and polycarbonate.

Poly(vinyl

chloride) [PVC]

– a widely used plastic, often heavily plasticised. It can be copolymerised with other monomers

such as vinyl acetate and methyl acrylate, and alloyed with many other

plastics. Because of the wide variety

and high percentages of additives used in ‘PVC’, this plastic is the one most

likely to present problems in complying with the requirements in EN 71-9.

Thermoplastic elastomer [TPE] – a synthetic rubber

commonly formed by the polymerisation of styrene with butadiene, isoprene or

other reactive olefin. It can be alloyed

with other polymers such as poly(phenylene ether).

Kraton® polymers are commercial block-copolymer elastomers based mainly on

styrene; several types are available: styrene-butadiene-styrene (SBS),

styrene-isoprene-styrene (SIS), styrene-ethylene/butylene-styrene (SEBS),

styrene-ethylene/propylene-styrene (SEPS) and polyisoprenes. SIS has been used to make teethers. Some of these elastomers have been used as a

replacement for PVC in some applications.

Monomers:

There

are requirements in EN 71-9 for certain types of toys that contain polymeric

materials not to release acrylamide, bisphenol A, formaldehyde, phenol and

styrene above set limits. In the case of

acrylamide, the limit is the analytical determination limit which is 0.02 mg/l.

Acrylamide: a water-soluble, crystalline

solid used in the manufacture of polyacrylamide, a polymer unlikely to be found

in toys.

Bisphenol

A: a chemical

used to make polycarbonate and some types of epoxy resins. Bisphenol A is unlikely to be detected in

plastic materials containing polycarbonate that are tested according to EN

71-10 & 11 unless the polycarbonate has been badly made, is badly degraded,

or has been exposed to alkalis or solvents – even so, the limit in EN 71-9 is

unlikely to be exceeded.

Formaldehyde: a volatile substance used in the

manufacture of phenol/formaldehyde, melamine/formaldehyde and urea/formaldehyde

resins and polyacetal. The resins are

mainly used as adhesives and to make resin-bonded wood-based materials such as plywood

and chipboard. Coatings made from

urea-formaldehyde and plastics made from polyacetal are likely to release a

small amount of formaldehyde unless the polyacetal has been surface treated to

prevent this; the amounts are unlikely to exceed the limit set in Table 2D of

EN 71-9.

Phenol: a substance with a low odour and

taste threshold used in the manufacture of polyphenylene oxide and

phenol/formaldehyde resins. It has been

found in PVC due to hydrolysis of certain stabilisers. Polymeric materials containing PVC should be

tested in the absence of a declaration that they do not contain or release

phenol. N.B. For inflatable toys this is

not a formal requirement but an advisory one.

Styrene: a reactive chemical used in the

manufacture of polystyrene, styrene-based elastomers (rubbers) and ABS and

polyester (alkyd) resins. Although

polystyrene often contains residual styrene, its release from polystyrene is

unlikely. However, in the absence of

migration data, testing should be carried out on styrene-based polymeric

materials to establish whether they release significant quantities of styrene

monomer.

Solvents

(migration):

Trichloroethylene: may be present in PVC and

elastomers.

Dichloromethane: used as a blowing agent for PU

foams and as a solvent for polycarbonate resins; may be present as part of the

adhesive used on seams.

2-Methoxyethyl

acetate, 2-ethoxyethanol, 2-ethoxyethyl acetate, bis(2-methoxyethyl) ether and

2-methoxypropyl acetate: these glycol ethers and glycol ether acetate esters find use as

solvents for lacquers and varnishes.

They are not likely to be found in uncoated polymers.

Methanol: a water-miscible alcohol

unlikely to be associated with polymers.

Nitrobenzene: a very toxic pungent solvent

that has been found present in EVA and polyurethane foams. Along with aniline it has also been found in

nigrosine dyes, which should not be used to colour toys.

Cyclohexanone: a pungent solvent, frequently

released from coatings which have not been fully aired after application,

especially from those used on PVC toys.

3,5,5-Trimethyl-2-cyclohexene-1-one,

also known as

isophorone: a solvent with a low-odour threshold that has been detected

from coatings on PVC toys.

Toluene: used to soften plastics and in

polyurethane manufacture; may be found in polyester resins. Can be present in paints and as part of

adhesive systems.

Ethylbenzene: occurs as residues in coatings;

also used in styrene manufacture, has been found present in HIPS.

Xylenes: may be present in PVC and

polyester resins, and as a residue in (phthalate) plasticisers.

Solvents

(inhalation):

Many

of the considerations that apply to textiles with respect to solvents also

apply to polymeric materials. The two

methods detailed in Annex A of EN 71-11 will determine all the volatile

solvents that have requirements in Table 2F of EN 71-9. A limited number of toy types need to comply

with these requirements; in the absence of suitable documentary evidence,

testing is advised of those that do.

Toluene: used to soften plastics and in

polyurethane manufacture; may be found in polyester resins. Toluene can be present in paint and as part

of adhesive systems.

Ethylbenzene: occurs as residues in coatings;

also used in styrene manufacture, has been found present in HIPS.

Xylenes: may be present in PVC; residue

in (phthalate) plasticisers.

Mesitylene: may be found in PVC and acrylic

resins.

Trichloroethylene: may be present in PVC and

elastomers.

Dichloromethane: used as a blowing agent for PU

foams; can be present as part of adhesive systems.

Hexane: used as a solvent in rubber

cements; has been found in expanded polystyrene and in polyurethane foams (from

its use as a blowing agent).

Nitrobenzene: a very toxic pungent solvent

that has been found present in EVA and polyurethane foams.

Cyclohexanone: a pungent solvent, commonly

released from coatings which have not been fully aired after application,

especially those used on PVC inflatable toys.

3,5,5-Trimethyl-2-cyclohexene-1-one

(isophorone): a

solvent with a low-odour threshold that has been released from coatings used on

PVC inflatable toys.

Plasticisers:

Unsurprisingly,

flexible plastics are more likely to have been plasticised than hard, rigid

plastics. Such plastics are also more

likely to release other chemical substances when subjected to migration testing.

EN

71-9:2004 only has requirements for 4 phosphate plasticisers, substances that

incidentally can also be used to impart flame-retardant properties to

polymers. Future editions of the

standard are likely to control more plasticisers but when EN 71-9 was agreed

there was uncertainty over the relative toxicity of alternative plasticisers

(especially with respect to some of the phthalate plasticisers) and the

intentions of the European Community over their control. The 4 controlled phosphate flame retardants

are classified as hazardous substances and should not be used in toys that are

likely to be mouthed. The limit is 0.03

mg/l, the determination limit of the method in the aqueous extract of the toy

material. It should be noted that the

analytical method described in EN 71-11 can be used to identify and detect many

other commonly-used organic plasticisers.

Triphenyl

phosphate: a

substance that has been used to plasticize PVC, vinyl copolymers (for example,

vinyl chloride–vinyl acetate), phenol-formaldehyde resins, phenylene oxide

resins and varnishes. Triphenyl

phosphate has been used in conjunction with antimony trioxide to flame-retard

wendy-houses.

Tri-o-cresyl

phosphate, tri-m-cresyl phosphate & tri-p-cresyl phosphate: these substances are collectively

known as tricresyl phosphate or tritolyl phosphate. Because of its toxicity, tri-o-cresyl

phosphate is also controlled as a flame retardant. Tricresyl phosphates have been used to

plasticize and flame retard: PVC, elastomers, phenolic resins, nitrocellulose

lacquers and poly(vinyl acetate) [PVA] varnishes.

Polymeric materials – Solvents and Monomers

The

following table applies to the listed polymerics in “pure” or homo-polymer form

only, when fabricated under normal manufacturing processes. Blends, alloys and

co-polymers (other than those listed) should be considered to

have an elevated risk.

|

Polymeric materials |

Monomers/Solvent residues likely to be present. |

Risk of non-compliance * |

Notes |

|

Acrylonitrile-butadiene-styrene

terpolymer ABS |

Styrene |

Low |

|

|

Ethylene-vinyl

acetate copolymer EVA |

None |

Negligible |

|

|

Ethylene-vinyl

acetate foams |

Nitrobenzene |

Medium |

|

|

Polyacrylates

PAc Acrylics Acrylates Methacrylates |

Acrylamide |

Negligible |

Unless

the material contains Polyacrylamide, in which case the risk is Medium |

|

Mesitylene |

Low |

|

|

|

Polyamide PA Nylon |

None |

Negligible |

|

|

Polycarbonate |

Bisphenol

A |

Low |

|

|

Dichloromethane |

Low |

||

|

Polyethylene PE LDPE MDPE HDPE |

None |

Negligible |

|

|

Polyester |

None |

Negligible |

|

|

Poly(ethylene

terephthalate) PET |

None |

Negligible |

|

|

Poly(methyl

methacrylate) PMMA |

None |

Negligible |

|

|

Polypropylene PP |

None |

Negligible |

|

|

Polystyrene

– All Types (inc. HIPS and expanded) |

Styrene |

Low |

|

|

Ethylbenzene |

Low |

|

|

|

Polystyrene

– Expanded only (in addition to above) |

Hexane |

Low |

|

|

Polyurethane

|

Nitrobenzene |

Low |

|

|

Toluene |

To be determined |

|

|

|

Polyurethane

foams |

Dichloromethane |

To be determined |

|

|

Nitrobenzene |

Medium |

|

|

|

Hexane |

Low |

|

|

|

Toluene |

To be determined |

|

|

|

Poly

(vinyl chloride) PVC (excluding

PVC mentioned below) |

Phenol |

Medium |

|

|

Trichloroethylene |

Low |

|

|

|

Cyclohexanone |

Medium |

PVC

coatings only. |

|

|

3,5,5-Trimethyl-2-cyclohexene-1-one/

Isophorone |

Medium |

PVC

coatings only. |

|

|

Mesitylene |

Low |

|

|

|

Xylenes |

Low |

|

|

|

Plasticisers |

Low |

|

|

|

Poly

(vinyl chloride) PVC in

sheet form used in inflatable toys. |

Cyclohexanone |

High |

|

|

3,5,5-Trimethyl-2-cyclohexene-1-one/

Isophorone |

High |

|

|

|

Polyoxymethylene

POM Acetal Polyacetal |

Formaldehyde |

To be determined |

|

|

Thermoplastic

Elastomer TPE |

Trichloroethylene |

Low |

|

|

Plasticisers |

Low |

|

|

|

Styrene

based TPE’s Kraton SBS SIS SEn BS SEPS |

Styrene |

To be determined |

|

|

* Definition of terms: Negligible = Monomers & Solvents

listed in EN71-9 which are unlikely to be present at any level. Low = the substance may

be present in the material but is unlikely to be released at a level that

would approach the limits given in EN71-9. Medium = A substance that may be present

in the material. Although uncommon the levels may exceed those given in

EN71-9. High = A substance that is likely to be

present in the material at a level that may exceed those given in EN71-9. To be determined = Insufficient knowledge

to assign risk at this time. |

|||

What is an organic compound?

An organic compound is any

member of a large class of chemical

compounds whose molecules contain carbon; for

historical reasons discussed below, a few types of compounds such as carbonates,

carbon oxides and cyanides, as

well as elemental carbon are considered inorganic.The

study of organic compounds is termed organic

chemistry, and since it is a vast collection of chemicals (over half of all

known chemical compounds), systems have been devised to classify organic

compounds. A few of the compound classes based on the functional

groups they carry are as follows:

·

Alcohols

·

Alkanes

·

Alkenes

·

Alkynes

·

Amides

·

Amines

·

Esters

·

Ethers

·

Imines

·

Ketones

·

Nitriles

·

Phenols

·

Polymers, including all plastics

·

Thiols

Many organic compounds are also of

prime importance in biochemistry:

·

Antigens

·

Polysaccharides, carbohydrates

and sugars

·

Enzymes

·

Hormones

·

Lipids and fatty acids

·

Proteins, peptides and amino acids

© 2005, 2010 Professional Testing & Consulting Ltd. All rights reserved.